|

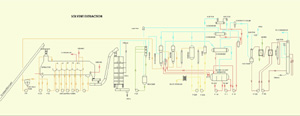

Flakes nom the preperation section are fed into an Extractor

with stainless steel belt. Level in hopper is controlled through

an ultrosonic level controller which regulates the speed of

the extractor.

Miscella is filtered through special wedgewire filters.

Distillation comprises of a series of heat exchangers

for heat recovery and evaporation of hexane. The oil is finally

stripped in a special stripper operating under low vacuum.

Series of specially designed condensors in tubes of stainless

steel are used for condensing the hexane vapours for recirculation.

The vent gases are specially scrubbed with mineral oil before

Discharge into the atmosphere. The hexane content of the gases

leaving the system are well below the lower explosion limits.

The solvent wet meal is fed through a vapour tight conveyor

into Desolventiser Toaster equipped with special level controllers.

Here the meal is desolventised in a series of stages and subsequently

toasted to remove the antinutritional factors.

The meal is subsequently dried and cooled for bagging.

|