|

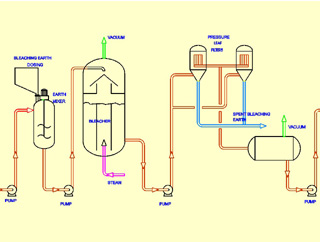

The neutrialised Oils are mixed with adequate quantity of

bleaching earth dosed through an accurate dosing system.

The mixed Oil is then transferred to a bleacher where Oil

under vacuum is agitated with steam. This also imparts the

wet bleaching effect.

The Oil is then filtered through pressure leaf filters. The

Filter leaves used are in special stainless construction with

the mesh imported from reputed suppliers.

The filter have special Pneumatic vibrators for discharge

of the cake, and special butterfly valve for easy opening

and discharge.

The bleached oil produced has very low phosphorous levels

and no soap.Preperation

|